About

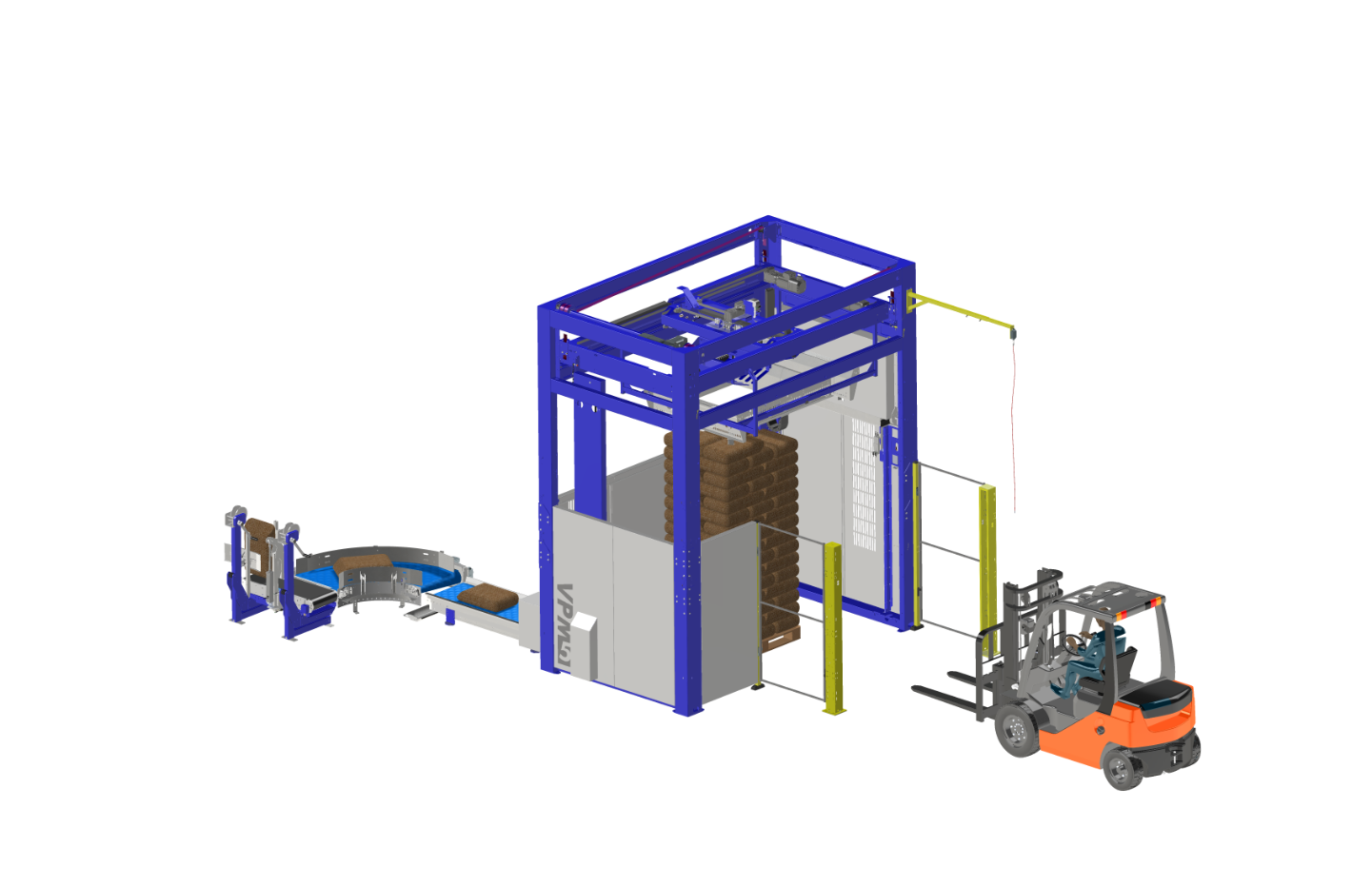

VPM-5 – A Compact Powerhouse

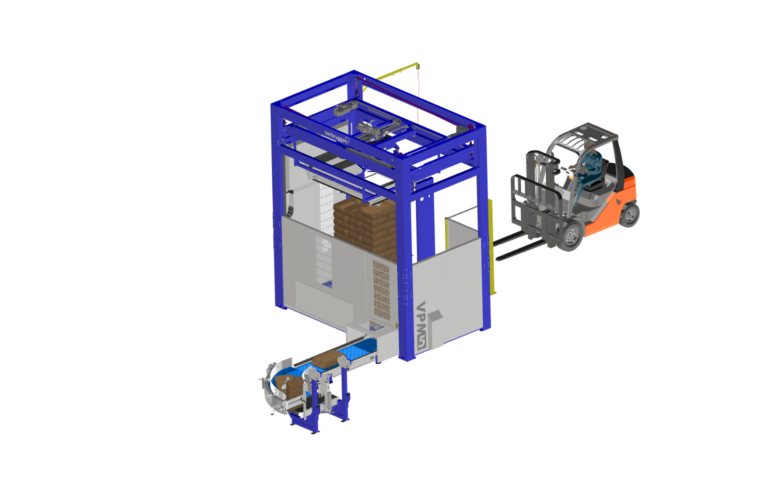

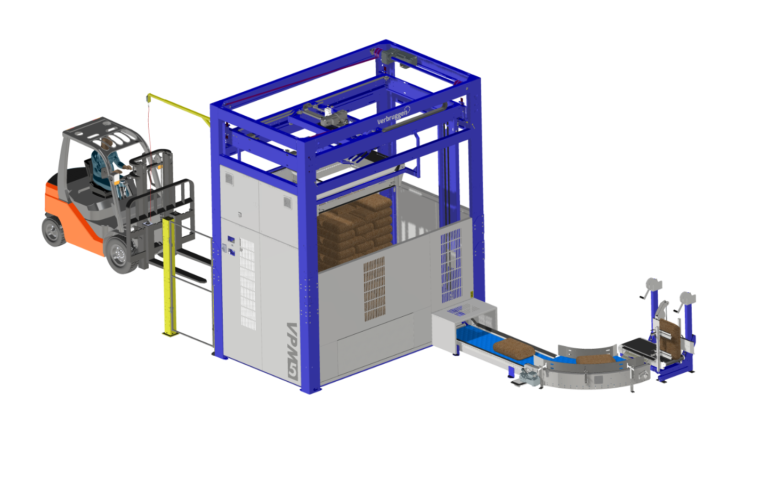

You don’t need a big machine to make your palletizing operations more efficient. With its smart and compact design, the VPM-5 is suitable for virtually any space and offers 10 customizable in-feed options. Ensuring precise product placement, the VPM-5 creates consistent, stable stacks each and every time, reducing labor dependency and boosting product line efficiency.

Bags enter at floor level, allowing a quick and smooth changeover from full to empty pallets using a pallet jack or forklift. The machine includes a user-friendly touchscreen and intelligent software. With remote access technology, our service team can provide immediate support from anywhere.

Specifications

| Model Features | |

|

Touch screen with user-friendly interface |

|

|

Easy configurable stacking patterns |

|

|

Remote access |

|

|

High infeed level |

|

|

Low infeed level |

|

|

Automatic stack / support transport |

|

|

Vertical compression |

|

|

4-sided stack enclosure |

|

|

Entrance protection |

|

|

Access platform |

|

| Specifications | |

|

Capacity (max. rate depending on configuration) |

|

|

5 units per layer |

550 units / hour |

|

13 units per layer |

550 units / hour |

|

Max. layer dimensions (mm) |

1600 x 1250 |

|

Package |

|

|

Maximum weight (kg) |

50 |

|

Minimum dimensions (mm)*1 |

350 x 220 x 50 |

|

Maximum dimensions (mm) |

880 x 590 x 325 |

Benefits

- Consistent and stable pallet stacks

- Compact design – suitable for almost any space

- Low power consumption

- Efficient and low maintenance

- High return and short ROI

Popular options and add-ons

- Pallet transport by roller conveyors, pallet dispenser, and wrapper

- Centering flaps (for bags less than 470 mm wide)

- Stand-alone wrapper

- External start for new pallet

- Extra collar section to reduce number of changes between pallet sizes

- Fork extension guides for forklift operators

Request Full Technical Sheet

Fill in your email address and we’ll send you the full technical sheet.

We won’t spam you or share your information.

Palletizer

3D animation

Best-selling

Beste-selling wrapper

with the VPM-5

A Verbruggen wrapper, when used in combination with a palletising machine, can significantly increase the value of the palletising process.

Using a Verbruggen wrapper alongside a palletising machine offers several benefits, including better product protection, reduced labour costs, and increased efficiency.

By securely wrapping the pallet, companies can ensure their products are protected from dust, moisture, and other environmental factors that may cause damage.

More information

Download our company

brochure or request

palletizing advice!

FAQ

Quick trivia

Complete this form and send to info@verbruggen-palletizing.com We will contact you as soon as possible regarding your inquiry.

1 year after signing off for installation and commissioning.

Please access to our Verbruggen Customer Portal to consult the user manual: Portal.verbruggen-palletizing.com

You can create a pattern yourself according to the instructions your operators who are trained by our team during the installation or follow the instructions in the user manual. In case you need our help, please contact our Service department so they can assist (remotely).

- Open the spare partsmanual for your machine. Identify the location and 8-digit item number of the part you need. Please visit our service page for more details about ordering spare parts. If you need any help identifying the right part, please feel free to contact us.

- You can also request a spare parts kit for your palletizer if you want to have spare parts on-hand.

Verbruggen has installed more than 1500 projects worldwide with good customer relations and references. Contact us at info@verbruggen-palletizing.com, and we will find a nearby site for you to visit!

- Less product damage

- Higher & stable stack

- More storage space

- Less stacking labor

- Strong ROI

- Proven technology

- High speed stacking

- Increase profitability

A palletizing system is a type or combination of automated equipment used in warehouses and production facilities to arrange and stack packed products on pallets. Palletizing systems can include a variety of different components, such as conveyor (accumulation) belts, check weigher, palletizing machine, sheet dispenser, wrapping and/or strapping machine, and pallet labeler, that work together to efficiently and accurately palletize products. Palletizing systems can be programmed to handle a wide range of products and can work quickly and accurately, reducing the amount of manual labor required in a warehouse or manufacturing facility. They are often used in conjunction with other types of automation equipment, such as weighing and packing equipment, to improve efficiency and reduce costs.

Palletizing refers to the process of arranging and stacking packed products on a pallet in a warehouse or production facility. The goal of palletizing is to create a stable and secure load that can be easily moved and stored using a forklift or pallet jack.

Palletizing can be done manually by workers or by using automated equipment, such as robots or conveyor systems. In a palletizing operation, the products to be palletized are typically brought to a central location, and then they are picked up and arranged on the pallet according to a specific pattern or configuration. The palletized products are then wrapped or strapped in place using packaging materials such as stretch wrap, mesh, paper, and strap band, and labeled with the necessary information for handling and storage. Palletizing is a key part of many logistics and supply chain systems, as it allows for the efficient and safe handling and storage of products.

Verbruggen’s innovative palletizing technology allows impressively stable and consistent product stacking, for almost any type and dimensions. Our machines are designed to stack the most difficult packagings including bags, boxes, cartons, crates, and even special product applications.

- Latest technology in Automation Industry 4.0

- Customized solutions designed for your packaging and capacity requirements

- Industry leading equipment solutions for optimal efficiency and durability

- First-class Customer Service and After Sales Support

The average delivery time of a palletizer to the end user is 10 weeks plus shipping, after order confirmation and down payment. But the actual duration always differs from project to project, depending on the project complexity, size, and the amount of project engineering needed for a customized solution.

There is a wide price range based on different models, configurations, and equipment complexity. We strive for an ROI of around 2-3 years, depending on functionality and application. We can provide you with an offer quickly after your project data submission to be processed into a layout and quotation.

Verbruggen palletizers are made for heavy-duty agricultural and industrial applications. Many are used daily for more than 25 years and have stacked 25+ million packaging.

Verbruggen palletizing machines are designed for quality and durability, delivering an incredible stable stack and consistent performance. This exceptional focus on dependability makes Verbruggen the preferred choice of many industry leaders. Additionally, our machines are cutting edge as a result of extensive R&D, meaning that we can stack the most challenging products on the market.

- Latest technology in Automation Industry 4.0

- Customized solutions designed for your packaging and capacity requirements

- Industry-leading equipment solutions for optimal efficiency and durability

- First-class Customer Service and AfterSales Support

Experience with stacking any type of products; bags, boxes, cartons, crates, wraps, even special product applications.

Welcome

How can we help you?

We are a second-generation family business based in the Netherlands, Europe, specializing in palletising machines.

With a focus on customer intimacy and supporting local communities, we offer reliable, efficient, and tailor-made palletizing solutions for businesses of all sizes worldwide.